INTRODUCTION

1. This is my judgment from the trial of this action concerned with three patents relating to microbial oils and their production. These oils can contain a high level of polyunsaturated fatty acids (“PUFAs”), such as an omega-3 PUFA called docosahexaenoic acid (“DHA”) which traditionally has been sourced from fish oil, and which is an important component of infant formula.

2. The Claimants (collectively “DSM”) and the Defendants (collectively “Mara”) are competing producers of such oils (it being unnecessary for present purposes to distinguish as between the two Claimants and as between the two Defendants).

3. DSM asserts infringement of three patents (from three different families). In order of priority date, the patents are as follows (there is no challenge to priority).

i) EP 2 921 155 (“EP155”) entitled “Methods for producing high-quality lipids by enzymatic liberation from biomass” (priority date 3 May 2002). It relates to the use of a protease enzyme in the process to extract microbial oil from Schizochytrium microorganisms. It expired on 4 May 2023;

ii) EP 3 530 740 (“EP740”) entitled “Thraustochytrids, fatty acid compositions, and methods of making and uses thereof” (filing date 19 March 2009 and no earlier priority date). It provides a new microbial oil, which is a crude oil product derived from a Thraustochytrid microorganism, which has a high triglyceride fraction and a high percentage of DHA in that triglyceride fraction.

iii) EP 2 576 801 (“EP801”) entitled “Extraction of lipid from cells and products therefrom” (earliest priority date 01 June 2010). It relates to a microbial oil extraction process which solves the emulsion problem without the use of organic solvents.

4. DSM were keen to emphasise that all three patents have been considered by the EPO Opposition Division (“OD”):

i) EP155 was maintained as granted by the OD. Opposition proceedings were commenced in 2020 by a strawman entity, and following oral proceedings on 28 September 2022 the opposition was rejected. That decision was not appealed.

ii) EP740 was upheld in amended form by the OD. Opposition proceedings were commenced in 2022 by a strawman entity (another opponent unrelated to the parties to these proceedings initially also opposed EP 740 but withdrew its opposition at an early stage). The First and Second Defendants in these proceedings each filed interventions in March and April 2023 respectively, on the basis of the present proceedings. Following oral proceedings held on 23 November 2023 the OD found claim 1 as granted invalid for added matter, but upheld EP 740 amended in a form corresponding to claim 2 as granted. An appeal to the Technical Boards of Appeal is outstanding, with the appeal hearing date yet to be set.

iii) EP801 was upheld in amended form by the OD. Opposition proceedings were commenced in 2020 by a strawman entity. The First and Second Defendants in these proceedings each filed interventions in March and April 2023 respectively, on the basis of the present proceedings. Following the oral proceedings of 10 and 11 September 2024 the OD found claim 1 as granted invalid for added matter, but upheld EP 801 on the basis of Auxiliary Request 2 (being claim 1, with step c1 (salt addition) and one or more of steps c2 to c4 being required). At the trial the written reasons of the OD were yet to be provided.

5. Mara counterclaims for invalidity on a variety of grounds. Much of the prior art comes from DSM. The same inventors are named on both Bijl and Hendrik, and Kobzeff (prior art to EP801) is closely related to EP155. One of the experts, Mr Dueppen, exhibited comparisons to show the common text. DSM has applied to amend unconditionally both EP740 (an amendment opposed on several grounds) and EP801 (opposed on the basis that the amendment does not cure the invalidity).

6. The claims said to be independently valid and infringed are:

i) EP155: claims 1 and 5.

ii) EP740: claims 1B and 2B (these being claims from the claim set at Annex B of a second amendment application, which is the only claim set now relied on).

iii) EP801: claims 1A, 6A & 7A (these being claims from the claim set at Annex A of the amendment application). I note in passing that shortly before trial, DSM confirmed that it no longer seeks to introduce claim 2A.

7. Mara has carried out (and proposes to carry out) a variety of processes to produce two oils: a lower-DHA oil called Mara DHA, and a higher-DHA oil called Mara DHA Plus. These use different microbial strains and different process conditions.

8. Mara DHA is Mara’s standard DHA microbial oil product obtained from a type of Thraustochytrid microorganism designated as strain ONC-T18 (or “T18”). Mara DHA Plus is Mara’s high DHA oil product (>55% DHA) obtained from a different Thraustochytrid designated as “G3”. There are a number of different versions of the processes in issue but the parties have agreed that infringement may be tried by reference to a limited number of exemplary processes.

9. In summary:

i) For EP155, the processes for production of both Mara DHA and Mara DHA Plus are said to infringe claim 1, but only the production of Mara DHA is now said to infringe claim 5. Subject to validity, infringement of claim 1 is admitted but infringement of claim 5 is denied. Claim 5 was relied upon as being independently valid for the purposes of sufficiency only (not obviousness), but in closing Mara indicated they did not pursue insufficiency of EP155.

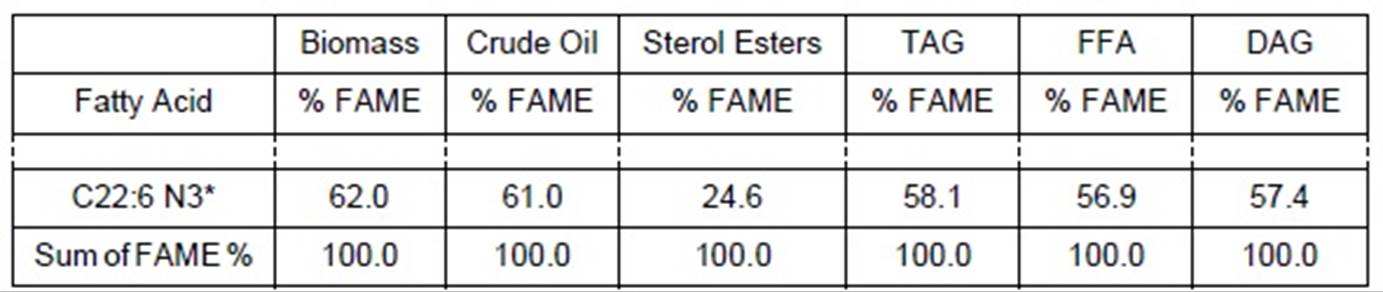

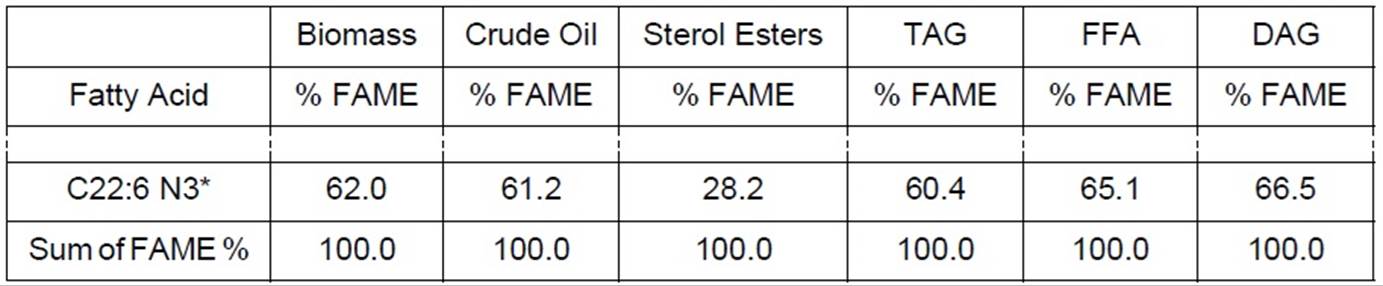

ii) For EP740, which claims a high DHA oil with certain features, only Mara DHA Plus is alleged to infringe. The only infringement issue for determination is over the numerical limits in claims 1B and 2B, which affects which batches fall within those limits.

iii) For EP801, the processes for production of both Mara DHA and Mara DHA Plus are said to infringe, which is denied. After recent streamlining of Mara’s case, the non-infringement points relate to pH (it being a requirement of the claim that the pH is raised to 8 or above).

10. Finally, and for reasons which will become apparent, it is necessary to introduce the concepts of upstream and downstream processing. Upstream processing covers strain selection, media development and process design to enable the production of a lipid rich biomass at a commercial scale and downstream processing covers cell inactivation, extracting the oil from the cells and recovering the crude oil, and refining the oil.

11. DSM called two expert witnesses. First, Mr Daniel Dueppen. He gave evidence from the perspective of the Skilled Bioprocessing Engineer, a person skilled in downstream processing. Mr Dueppen has 40 years of experience relating to the use of microorganisms to produce a range of substances with potential medical, human or animal health applications. He is currently Director of Bioprocess Development at HTL Biotechnology in New Jersey, working on fermentation and downstream processing. Mr Dueppen has a degree in Agronomy, which he completed in 1985. Up until 2000, he had roles in companies involved in producing products by fermentation. In 2000, Mr Dueppen joined OmegaTech Inc. as Production Manager where he worked on, and improved, the production methods of one of the first commercial DHA omega-3 oils produced from a microorganism. After OmegaTech was acquired by Martek in 2002, Mr Dueppen worked as RBD Production Manager, taking control of the refining, bleaching and deodorizing process. This included co-managing and designing RBD production as part of the construction of a major facility for microbial oil production. In 2004, as Third-Party Production Manager, he worked on qualifying omega-3 and omega-6 based products (in particular microbial oils) to be used by food and infant formula customers. Between 2007 and 2010, Mr Dueppen worked at Microbia Inc as Director of Process Development, leading a team of engineers and chemists to develop solvent extraction, separation, purification, crystallization, and recovery processes of carotenoids.

12. Second, Dr James Wynn who gave evidence from the perspective of the Skilled Microbiologist, a person skilled in upstream processing. Dr Wynn has over 25 years of experience in industrial biotechnology and studying the production of microbial oils. In his current role as Head of Global Research & Development at AB Mauri, Dr Wynn leads a global team of specialist centres that focus on microorganism strain selection and development to provide novel and improved products that are used in the Food and Beverage Industry. He is also a contributing author to the textbook “Single Cell Oils” (including the 2005 and 2010 editions).

13. Dr Wynn’s first degree was in Applied Biology at the University of Cardiff. He completed a PhD in Applied Biology at the University of Hull in 1993, before starting post-doctoral positions at the Universities of Nottingham and Hull. He remained in the latter position until 2001, studying the biosynthesis of PUFAs in oleaginous microorganisms, including fungi and microalgae, alongside Professor Colin Ratledge (a prominent figure in the field of single cell oils).

14. Between September 2001 and September 2005, Dr Wynn worked as a Senior Scientist at Martek, leading the molecular biology team which was researching the biochemistry of key DHA producing microorganisms. That included work on Martek’s original DHA biotechnology, DHASCO oil. Later, in 2005, Dr Wynn was promoted to Principal Scientist and led a research collaboration with DSM for the development of the fungal fermentation process for the production of ARASCO. Dr Wynn left Martek in May 2009 to join the Michigan Biotechnology Institute and in 2016 joined AB Mauri in his current role.

15. Mara called a single expert witness, Dr David Kyle. Dr Kyle completed a degree in marine biology in 1974 at the University of Victoria in Canada. He obtained his PhD in 1980 from the University of Alberta on the biochemistry of plant lipids. Until 1984 he conducted post-doctoral studies at Michigan State University in plant molecular biology and biochemistry using single cell algae as model systems, which included work in institutes in Paris, Tokyo and Colchester. In 1984, Dr Kyle spent a year as a Research Scientist with Lockheed Martin working with NASA on designs for self-contained life support systems for orbiting space labs and lunar colonies. In 1985, he and the rest of the biotech team founded Martek, with the purpose of studying metabolites from algae and their potential use as foods, pharmaceuticals and diagnostics. At Martek he was initially Director of Business Development and Research Manager, and then Senior Vice President of Research and Development, responsible for directing research concerning microbial oil production and the utilisation of omega-3 and omega-6 PUFAs. He was heavily involved in the development of Martek’s Designer Single Cell Oils program, which produced oils from the microorganisms Crypthecodinium and Mortierella marketed under the names DHASCO and ARASCO. He had primary responsibility for interacting with the external commercial partners, researchers and clinicians who wanted to know more about, or obtain samples of, the oils. Professor Ratledge has credited Dr Kyle with the “major breakthrough” of recognising that microorganisms could be the key to providing a supply of DHA, and of identifying a potential microbial source at Martek.

16. In 2001, Dr Kyle left Martek and founded and served as President and CEO of Advanced BioNutrition Corporation, where the focus was on the use of extracted bio-meal as animal feed. Like Dr Wynn, Dr Kyle is a contributing author to the 2005 and 2010 editions of the textbook “Single Cell Oils”.

17. In 2008 he retired from full time work in the microbial oils field. In 2009, he was inducted into the US Space Technology Hall of Fame for his contributions to science and industry, especially for the development and commercialisation of DHASCO and ARASCO and their incorporation into infant formulas. Dr Kyle then formed his own consultancy company, and in 2013 joined the academic founders of Evolve Biosystems in Davis, California and served as Managing Director, then CEO and subsequently Executive Chairman, until the company was reorganised and renamed Infinant Health early in 2022.

My assessment of the Experts

Mr Dueppen

18. DSM submitted that Mr Dueppen was a patently honest witness who gave fair and measured answers to all the questions he was asked. For their part, Mara had no criticism of him whatsoever, agreeing that he was fair and balanced in his approach. Subject to the points which I address below (at [43]-[45]) and which concern or stem from the approach which DSM’s experts were invited to take (therefore not really their fault), I largely agree.

Dr Wynn

19. DSM submitted that Dr Wynn was a model expert witness. Mara was critical only of some isolated parts of his evidence, including in particular his evidence relating to a literature search. Mara submitted that, subject to what they characterised as ‘that significant lapse’ and a couple of other minor instances, he was trying his best to assist the court fairly on the matters which fell on his side of the split between himself and Mr Dueppen. I consider Mara’s points of criticism below, but in general, but subject to the same qualification I mentioned for Mr Dueppen, I agree that Dr Wynn was a good witness.

20. It was not surprising that Mara made only very limited criticisms of Dr Wynn and none of Mr Dueppen because Mara’s case in closing inevitably relied very heavily on their evidence - inevitably because of what became apparent in the cross-examination of Dr Kyle.

Dr Kyle

21. Despite Dr Kyle’s very considerable experience in this field, I regret to say that his evidence proved unsatisfactory in a number of respects. By way of example, I gained the impression that Dr Kyle had not adequately grasped the need to eliminate hindsight when considering the important issue of obviousness, despite setting out the Pozzoli approach in his evidence. Equally, he did not appear to have properly understood the concept of common general knowledge or the need to avoid speculation. However, it does not appear to be necessary to set out all the respects in which DSM were critical of his evidence because Mara accepted that overall his evidence and approach was shown to be unsatisfactory in several respects. Accordingly, Mara did not seek to persuade the Court to prefer Dr Kyle’s evidence over that of the DSM expert witnesses.

22. In some cases, such a concession would be fatal. Mara faced up to the problem caused by Dr Kyle’s evidence, contending that they could establish their case on each patent relying on the evidence of Mr Dueppen and Dr Wynn - this was particularly the case regarding EP155.

23. Having said all that, there remain parts of Dr Kyle’s evidence which were not challenged, both in his written evidence and on points elicited by DSM in their cross-examination of him. However, where his evidence was disputed, I will not rely on it unless either Mr Dueppen or Dr Wynn effectively agreed with the point in the course of cross-examination.

24. Before leaving the topic of the expert evidence, I should briefly outline how the expert evidence developed, particularly during the trial.

25. The initial exchange of expert evidence took place on 3 July 2024, with reply reports on 21 August. On 10 September 2024, Wynn 3 was served, responding to certain points in Kyle 2. Dr Kyle then responded to Wynn 3 in Kyle 3 dated 19 September 2024.

26. The cross-examination of Mr Dueppen started on Day 2 - Wednesday 2 October and on that day he was cross-examined as to how the Skilled Team could tell the difference between a crude oil and a refined oil (see further below). Evidently in response to that, on 3 October, Powell Gilbert posed a question to Dr Wynn which he addressed in Wynn 4, dated 4 October 2024.

27. Mr Dueppen’s cross-examination concluded during the morning of day three (Thursday 3rd October), whereupon we had to break until Monday 7 October. That day started with DSM’s application to rely on a new expert report from Dr Wynn (Wynn 4) and I heard lively argument on that issue. The arguments were very evenly balanced, so I reserved my ruling. Pending that Dr Wynn was cross-examined on Wynn 1-3. My decision to admit Wynn 4 was communicated to the parties early on Tuesday 8th. Mara had shown Wynn 4 to Dr Kyle and he had managed to draft a short report from Dr Kyle in response - Kyle 4. In order to make the best use of time, and as agreed, the cross-examination of Dr Wynn concluded on Wynn 1-3, whereupon I gave my reasons for admitting Wynn 4 whilst Dr Wynn was given the opportunity to consider Kyle 4. Dr Wynn then went back into the witness box and was cross-examined on Wynn 4.

28. There are two issues to resolve regarding the Skilled Person/Team. The first was a curious dispute debated between the parties over the Skilled Team but one which has ramifications as to the approach to prior art. The second issue was not identified or tackled directly, but it emerged from the differing approaches taken to certain of the prior art. It concerns whether the Skilled Team only operated and were interested in commercial (i.e. industrial) scale processes. I address these issues in turn.

29. The relevant law is settled: although the skilled person/team is a hypothetical construct, its composition and mindset is founded in reality. As Henry Carr J. said in Garmin v Philips [2019] EWHC 107 (Ch) at [85](v), the combined skills (and mindsets) of real teams are what matters.

30. It was common ground that the skilled person / team involved in the production of microbial oils would have skills relating to:

i) upstream processing, which covers strain selection, media development and process design to enable the production of a lipid rich biomass at a commercial scale; and

ii) downstream processing, which covers cell inactivation onwards (i.e. lysis, extraction of the oil from the cells, recovery of the crude oil, and refining the oil).

31. Although the first dispute was framed as whether a single skilled person would cover both areas, in fact the dispute between the parties appeared to be over the degree of communication and interaction between the upstream and downstream sides.

32. Dr Wynn and Mr Dueppen explained that upstream and downstream processing are distinct areas - in practice they may even be in physically distinct locations. Although the separate teams may work closely together, in their view both areas would not fall within the expertise or interest of a single skilled person. In their view, upstream processing is the province of a person with expertise and relevant experience in the field of microbiology (a “Skilled Microbiologist”), while downstream processing is the province of person with expertise and relevant experience in bioprocess engineering (a “Skilled Bioprocessing Engineer” or “SBE”).

33. In contrast, Dr Kyle considered that a single skilled person would have expertise in both upstream and downstream processing. He explained that such a person would have several years’ industry experience generally in the field of microbial oils. Dr Wynn and Mr Dueppen disagreed that such persons exist.

34. DSM acknowledged first, that many of the core CGK concepts were similar regardless of the makeup of the skilled team / person, in particular those relating to the fundamental principles of chemistry and biology and second, that in many instances it was not material if an issue is considered from the perspective of one of the members of the skilled team, as described by Dr Wynn and Mr Dueppen, or a single person, as described by Dr Kyle. In those contexts, it appears DSM were content to refer simply to the Skilled Team.

35. However, DSM made their position clear that the disagreement on this issue could affect the correct approach to obviousness and the prior art. Their point was that it is wrong in law and unfair to a patentee to consider issues such as inventive step from the perspective of a “super-skilled individual” as posited by Mara, rather than a notional team that reflects the make-up of real teams as described by Dr Wynn and Mr Dueppen. In such contexts, DSM indicated they would use the experts’ nomenclature of Skilled Microbiologist and Skilled Bioprocessing Engineer to describe the respective upstream and downstream members of the team.

36. I will keep all these points in mind, particularly as to DSM’s warning that Mara’s case required a ‘super-skilled individual’.

37. That leads me to the second issue. There is one respect in which I considered DSM’s characterisation of the Skilled Team to be too limited. DSM appeared to me to be focussed almost exclusively on processing at commercial scale, with the members of the team apparently only being interested in and only having experience in processing at commercial scale. This seemed to me to be unrealistic, not least because any commercial processing would have to have been scaled up from much smaller and experimental processes, at least some of which would have to take place at very small scale in a laboratory i.e. experiments at beaker scale.

38. I do not believe that the Skilled Team would only have experience of processing at commercial scale, or be limited, in effect, to technicians whose job is to keep the commercial processes running. In my view, they would also have experience of experimenting in the lab and then scaling up. They would have the (non-inventive) ability to develop processes, not just run them.

39. This is confirmed by consideration of the Patents and many of the Examples in them which, in the main, reflect small-scale laboratory experiments. Implementing any of the Patents would require trials in the lab for proof of concept followed by scale-up experiments as necessary.

40. This point is also confirmed by the extracts from “Single Cell Oils; Microbial and Algal Oils”, edited by Zvi Cohen and Colin Ratledge (‘the SCO Book’) which were put to Mr Dueppen in cross-examination, and by the identity and background of the authors of chapters in that book. I should explain the SCO Book was published in 2005 but arose from a symposium in May 2003 organised by Dr Kyle ‘that covered many of the on-going projects in this area’. Both sides agreed the SCO Book reflected the CGK at May 2002.

41. The SCO Book shows that there was an active (if relatively small) community of people working around the world both in commercial companies and in academia, researching microbial oils and processes to obtain them. Perhaps the best example from the academic side is Dr Barclay, but I should also mention Professor Colin Ratledge and Zvi Cohen, the editors and co-authors of the SCO Book.

42. In this regard, I refer to Chapter 13, entitled ‘Down-Stream Processing, Extraction and Purification of Single Cell Oils’ by Colin Ratledge (University of Hull), Hugo Streekstra (DSM), Zvi Cohen (Ben Gurion University) and Jaouad Fichtali (Martek). Whilst in large part this Chapter considers downstream processing at commercial scale, on p240 there is specific mention of extracting the oil from small samples of the biomass taken from laboratory fermenters. The combination of the authors of this (and other Chapters in the SCO Book) also confirms the sort of links between academia and industry that one would expect to exist.

43. This brings me to the qualification I have about the evidence of Mr Dueppen and Dr Wynn. I gained the impression that their focus was very much on the commercial scale production processes with little or no attention being paid to anything outside that. If there is any fault involved, it lies not with the experts but with the topics they were invited to cover i.e. those instructing them. It is evident that it suited DSM’s case to focus on large scale commercial processing.

44. This focus was also promoted by DSM’s adoption of the division between upstream and downstream processing. Whilst the adoption of these terms was legitimate, it needs to be kept in mind that reference to them tends to put one in mind of commercial processing. The use of these terms suited DSM’s focus.

45. However, as I discuss below, answers given by both Mr Dueppen and Dr Wynn in cross-examination served to prove that enzymatic lysis and other non-mechanical lysis methods were CGK because they would be used and explored at small scale in the laboratory, either in industry or in academia. I also gained the impression that both Mr Dueppen and Dr Wynn had a tendency to stick to the party line, as expressed in their written evidence. However, for the most part, I can rely on what Mr Dueppen and Dr Wynn said in their live evidence.

46. Finally, having said all that, the focus on commercial processing appeared to be consistent with the evidence as to the commercial barriers facing any new entrant (see [174] below).

THE COMMON GENERAL KNOWLEDGE

47. Before moving to what was agreed CGK (and the areas of dispute), I consider it is necessary to say something about the sources of CGK in this field, on which there was broad agreement between the experts.

48. As Dr Kyle observed, there was no standard textbook in the microbial oils field. Such reference books as existed arose from various symposia, typically organised by the AOCS. Dr Kyle referenced two books, with which the Skilled Team would be familiar: first, “Industrial Applications of Single Cell Oils” (1992) edited by himself and Colin Ratledge, and second, the SCO Book. Although this was published in January 2005, it arose from a symposium which Dr Kyle organised for the AOCS in May 2003 and, as noted in the preface, also echoes two earlier AOCS conferences, the first being a 1982 conference held in Toronto and the second being the AOCS conference from May 1992 in Chicago. Between them, the experts exhibited 7 chapters from the SCO Book and I was supplied with a hard copy of the book itself, a relatively slim volume of some 250 pages. The experts also referenced certain papers.

49. Thus, it appears that the primary source of CGK were symposia and conferences, with certain of the topics discussed being then recorded in the books Dr Kyle referred to. Experts on both sides also referenced certain journals. Having referenced the SCO Book, Dr Wynn said:

‘I also believe sources of CGK for the Skilled Microbiologist would have included key lipid-related developments published in the following journals: Lipids, Applied Microbiology, World Journal of Microbiology and Biotechnology, Advances in Applied Microbiology, Applied and Environmental Microbiology, Nature Microbiology, and Nature Biotechnology. The Skilled Microbiologist may have attended conferences such as the AOCS Annual Meeting, International Conference on Algal Biomass, Biofuels and Bioproducts, Algae Biomass Summit and the Annual Meeting of the Society for Industrial Microbiology and Biotechnology.’

50. Mr Dueppen also made an important point about the effect of commercial companies keeping specific details of their processes confidential, so that reference was made to regulatory submissions and published patent filings:

‘The basic scientific principles underpinning the work of the Skilled Bioprocessing Engineer would be found in standard university chemistry, biochemistry and bioprocessing textbooks. More specific, industrially applicable techniques would also be taught at various continuing education courses such as those by the American Institute of Chemical Engineers (AIChE) and the American Chemical Society (ACS). These organizations host conferences and events at which industry-specific knowledge relevant to the field of extraction of oil from

microbes and plants was discussed, although typically at a high level as many companies kept the more specific details of their processes confidential as trade secrets or until they were patented. For the same reason there were relatively few pieces of academic literature addressing more industry-specific issues facing the Skilled Bioprocessing Engineer. In addition the key companies in the field kept informed of others’ activities, including via their regulatory submissions and patent filings.’

51. Mr Dueppen also referred to the SCO Book as the most comprehensive summary of the academic and non-confidential industrial work in the field and as a good source of CGK. So there was clear agreement that the SCO Book is representative of the CGK at the EP 155 Priority Date. However it remains the case that, in this field, a lot of the CGK was not recorded in any textbook.

52. The remainder of this section is based on the Statement of Agreed CGK provided by the parties. I was told that the agreed points are not affected by the parties’ different positions on the Skilled Team. The Statement of Agreed CGK started with a section containing a series of definitions of some key terms, and then proceeded with three further sections, each describing the agreed CGK at each of the three priority dates. The parties identified a number of disputes. It is convenient to decide the minor ones as I proceed through each section.

53. Although the CGK does not change a great deal between the various priority dates, I prefer to set out the CGK (and decide the disputes) at each priority date in the context of each patent.

54. AOCS (the American Oil Chemists’ Society) - an international professional organisation founded in 1909 and based in Urbana, Illinois for those involved with the science and technology related to fats, oils, surfactants, and other related materials;

55. Arachidonic acid - often abbreviated to ARA, is a polyunsaturated omega-6 fatty acid, often also referred to as 20:4, 20:4 n-6, or 20:4 ω-6;

56. ARASCO® or Arachidonic Acid Single Cell Oil - a single cell oil developed by Martek from the fungi Mortierella alpina which contains primarily only one PUFA, arachidonic acid, in its fatty acid profile;

57. DHASCO® or Docosahexaenoic Acid Single Cell Oil - another single cell oil developed by Martek from the algal species Crypthecodinium cohnii which contains primarily only one PUFA, docosahexaenoic acid, in its fatty acid profile;

58. Docosahexaenoic acid - often abbreviated to DHA, is a polyunsaturated omega-3 fatty acid, often also referred to as 22:6, 22:6 n-3 or 22:6 ω-3;

59. Docosapentaenoic Acid - often abbreviated to DPA, is a polyunsaturated fatty acid, often referred to as 22:5. There are both omega-3 and omega-6 forms of DPA referred to as 22:5 n-3; 22:5 ω-3 and 22:5 n-6; 22:5 ω-6 respectively;

60. Eicosapentaenoic acid - often abbreviated to EPA, is a polyunsaturated omega-3 fatty acid, often also referred to as 20:5, 20:5 n-3 or 20:5 ω-3;

61. GRAS or Generally Recognized As Safe – the status given by the United States Food and Drug Administration to a chemical or substance added to food if it is considered safe by experts under the conditions of its intended use;

62. Phospholipids - a class of lipids which have a molecular structure comprising a hydrophilic "head" containing a phosphate group and two hydrophobic "tails" derived from fatty acids;

63. Polyunsaturated Fatty Acids – often abbreviated as “PUFAs” - are a type of fatty acid characterised by a backbone having two or more carbon–carbon double bonds. They can be characterised as omega-3 PUFAs or omega-6 PUFAs depending on the position of the double bonds;

64. Structural Lipids - those lipids that comprise the lipid bilayers in the cell membrane and cellular organelles. Structural lipids are primarily phospholipids.

65. Storage Lipids – those lipids which provide energy to a cell. Storage lipids are primarily triglycerides;

66. Triglycerides (more correctly referred to as triacylglycerides but often also abbreviated to “TAG” or “TG”) - a class of lipids consisting of three fatty acid chains linked by a glycerol backbone.

67. The following matters were agreed CGK at the EP155 Priority Date namely 3 May 2002.

68. Lipids are an essential part of the human diet. In chemical terms, lipids are defined very broadly, according to their chemical properties rather than their structure. The definition of a lipid encompasses a huge variety of chemicals including sterols, carotenoids, polyhydroxylalkanoates, triacylglycerols (TAGs, also referred to as triglycerides, TGs or neutral lipids), and phospholipids (also referred to as polar lipids). Fatty acids can be considered the structural units of fats or lipids, in much the same way as amino acids are the structural units of proteins. In some lipids (for example, TAGs and phospholipids), the fatty acids are covalently bonded to a glycerol backbone via an ester linkage that is shown in the orange box in Figure 1 below.

Figure 1: The major forms of fatty acids in cells

69. There are a large variety of fatty acids that differ in their chemical structure and, therefore, in their chemical characteristics. The fatty acid composition, often referred to as the fatty acid profile, of a lipid has a large impact on its physicochemical properties. Fatty acids play key roles in the function of lipids in biological cells and certain fatty acids play vital roles in human and animal development and health. Fatty acids, and the lipids they form, also have commercially significant applications in the food industry (cooking oils/fats, cocoa butter, etc.) and chemical industry (detergents, surfactants and lubricants).

70. Fatty acids are simple lipids, and consist of a nonpolar (‘fatty’) hydrocarbon chain terminating in a polar carboxylic acid (carboxyl) group). Generally speaking, fatty acids having fewer than 6 carbon atoms in the hydrocarbon chain are referred to as short chain fatty acids. Medium chain fatty acids are those with hydrocarbon chains of from 6 to 10 carbons, long chain fatty acids are those having 12 to 18 carbons in the hydrocarbon chain and very long chain fatty acids have hydrocarbon chains of 20 or more carbon atoms. Once the carbon chain length exceeds approximately six carbons, then the hydrophobic nature of the hydrocarbon chain dominates the hydrophilic properties of the polar carboxylic acid group, and the molecule overall takes on the hydrophobic characteristic of lipids (i.e. being insoluble in water).

71. With minor exceptions, the fatty acid residues in lipids are straight acyl chains with a carboxylic acid group at one end and a methyl group at the other end. The structure of fatty acids can vary in any one (or more) of three ways:

i) the number of carbon atoms in the carbon chain;

ii) the number of carbon–carbon double bonds (C=C) they contain; and/or

iii) the position of these double bonds.

72. Some example fatty acids to illustrate this variation are shown below:

Figure 2: The chemical structure of certain fatty acids

73. As the length of the fatty acid increases, the melting point of the fatty acid tends to increase. Conversely, the addition of double bonds into the fatty acyl chain tends to cause the melting point of the fatty acid to decrease. If the fatty acids contain no carbon-carbon double bonds (C=C) they are known as ‘fully hydrogenated’ or ‘saturated’ fatty acids, in contrast, ‘unsaturated’ fatty acids have one or more double bonds in the hydrocarbon chain. Fatty acids with hydrocarbon chains containing two or more double bonds are also referred to as polyunsaturated fatty acids (PUFAs).

74. PUFAs can exist in a number of molecular forms, including: (i) as a free fatty acid; (ii) as an ester; (iii) as a phospholipid and (iv) as a triglyceride (a.k.a. triacylglyceride, triacylglycerol, TG or TAG).

75. Phospholipids are comprised of a glycerol molecule wherein one of the hydroxyl groups is covalently attached to a polar phosphate group and the remaining two hydroxyls are esterified to fatty acids. Because of the presence of the polar phosphate-containing head group, phospholipids are not entirely hydrophobic but display amphiphilic properties. Amphiphilic refers to the fact that phospholipids possess a polar region that is hydrophilic (attracted to water) and a region that is nonpolar and hydrophobic (repelled by water).

76. The amphiphilic nature of phospholipids allows them to perform a vital role in all cells, as the membrane which separates the cell’s intracellular components (DNA, RNA, proteins etc.) from the outside aqueous environment is comprised primarily of a phospholipid bilayer. The phospholipids self-align into a bilayer with the hydrophobic parts in close contact forming the hydrophobic inner core of the membrane and the hydrophilic ends (phosphate groups) being attracted to the aqueous environments both outside and inside the cells. Figure 3 illustrates the lipid bilayer cell membrane.

Figure 3: Diagram of a cell membrane comprising a phospholipid bilayer

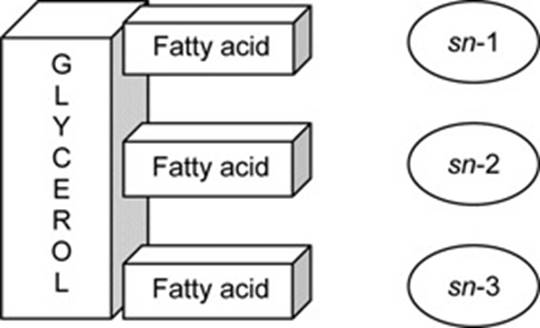

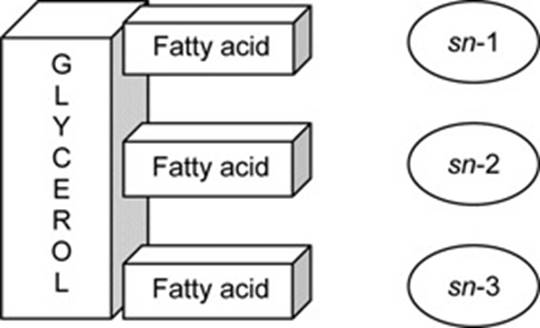

77. The other dominant form of fatty acyl lipids in cells are TAGs, having three fatty acid residues esterified to the glycerol backbone (see diagram in Figure 4 below, where each position on the glycerol backbone is typically labelled sn-1, -2 and -3). TAGs are hydrophobic molecules which will coalesce with other TAG molecules to form an oil droplet (oil body) within the cell. Glycerols having only one or two fatty acid ester substituents are similarly known as mono- and di-glycerides respectively.

Figure 4: Block diagram of a TAG

78. In contrast to phospholipids, in most cells, TAGs serve no specific physiological function (e.g. they do not form cell membranes), but they do act as storage molecules. TAG is particularly suited to the role of an energy and carbon store as it is a very concentrated form of energy; fat stores approximately twice the energy per unit mass as protein or starch.

79. Triglycerides (along with very small quantities of diglycerides and monoglycerides) are the predominant constituents of oils and fats of commercial importance. Indeed, most of the lipids we consume daily as part of our diets are in triglyceride form, either as a liquid oil (e.g. vegetable oil) or as a solid fat. Commercial oils are generally devoid of phospholipids as they are removed during refining (as discussed below).

80. The naming of fatty acids can be a somewhat confusing topic, as a number of names derived in different ways can be (and routinely are) given to any given fatty acid. In many cases, these names are used interchangeably, even within the same document. The table below includes a summary of the systematic, common and numeric names of some of the fatty acids relevant to these proceedings:

|

Systematic name |

Common name |

Abbreviation |

Numerical designation |

|

(all-cis)-5,8,11,14-eicosatetraenoic acid |

Arachidonic Acid |

ARA |

20:4 n-6 |

|

Eicosapentaenoic acid |

Timnodonic acid |

EPA |

20:5 n-3 |

|

Docosapentaenoic acid |

Clupanodonic acid |

DPA |

22:5 n-3 and

22:5 n-6 |

|

Docosahexaenoic acid |

Cervonic acid |

DHA |

22:6 n-3 |

|

Heptadecanoic acid |

Margaric Acid |

HDA |

C:17 |

81. The numerical designation takes the form X:Y n-Z, where X is the number of carbons in the acyl chain, Y is the number of double bonds contained in the acyl chain, and Z is the number of carbons from the last double bond to the terminal methyl group (inclusive) and therefore informs the reader which series (n-3, n-6 or n-9) the fatty acid belongs to.

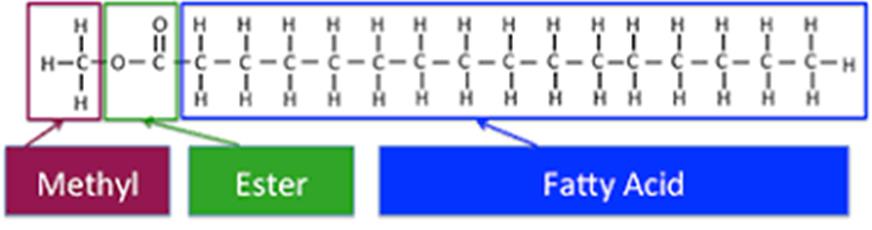

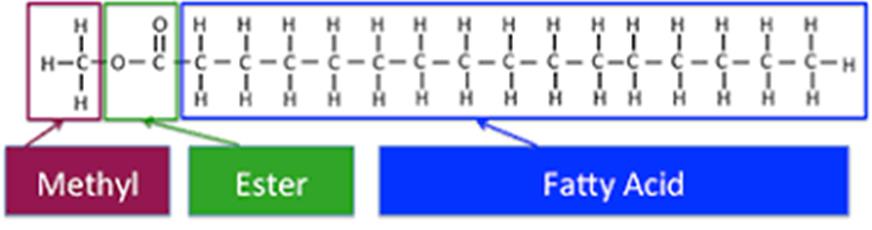

82. Fatty acid methyl ester analysis, also known as FAME lipid analysis, is a method used to identify and quantify the fatty acid composition of lipids in biological samples. The process involves extracting lipids from a sample, converting them from more complex phospholipids, mono-, di- or triglycerides into simple methyl esters of the individual fatty acids through a chemical hydrolysis reaction, and then analysing the resulting methyl esters using techniques such as gas chromatography.

Figure 5: Molecular structure of a FAME

83. In most cells (animal, plant, and microbial), fatty acids are synthesised through the action of an enzymatic complex called fatty acid synthase. The building blocks of fatty acids are molecules containing 2 carbons (acetyl-CoA) and, as such, the majority of fatty acids found in nature possess even numbers of carbon atoms in their backbone, as the fatty acid synthase enzyme acts by repeatedly joining these two carbon blocks together. There are some microorganisms that utilise a 3-carbon molecule (propionyl-CoA) as a building block, which means the resulting chain can have an odd number of carbon atoms, although such microorganisms are rare.

84. Eukaryotes (i.e. organisms having cells containing a nucleus, which include animals, plants, fungi and many unicellular organisms) primarily synthesise PUFAs by an oxygen dependent reaction that involves the elongation and desaturation of the shorter fatty acids. Humans and animals are capable of synthesising certain PUFAs with chain lengths from 18 to 22 carbons, however they generally do not possess several key enzymes to allow the production of certain other key long chain PUFAs described as essential fatty acids. In particular, the longest and most unsaturated fatty acids commonly found in nature, eicosapentaenoic acid (EPA), 20:5 and docosahexaenoic acid (DHA), 22:6 are only produced in small amounts by animals and humans. As a result, preformed EPA and DHA are important nutrients for most animal species and humans. DHA and EPA are omega-3 fatty acids (n-3/ω-3), and the molecular structures are shown in Figure 2 above.

85. The production and use of olive oil as a part of the human diet dates back more than 3 millennia. It has also been apparent throughout history that oils and fats are useful sources of metabolic energy. By the 1950s, research into fatty acids as a source of nutrition had become more focused on the importance of the degree of unsaturation, and since the 1960s, dietary recommendations have consistently advised reducing total dietary fat, and replacing saturated fats with unsaturated fats (i.e., vegetable oils). By the mid-1980s the growing recognition of the cardiovascular health benefits associated with PUFAs (especially EPA and DHA) found in fish oil, led to a major expansion of fish oil supplement sales in health food stores and pharmacies around the world, as discussed below.

86. Another important essential fatty acid is arachidonic acid (ARA). ARA is an omega-6 fatty acid (n-6/ω-6) PUFA with 20 carbons but only 4 carbon-carbon double bonds, and the molecular structure of ARA is shown in Figure 6 below.

Figure 6: Molecular structure of ARA

87. EPA is a precursor to anti-inflammatory compounds (eicosanoids and prostaglandins) that support cardiovascular health. DHA is the predominant polyunsaturated fatty acid in the brain and retina and is found in high concentrations in heart tissue. DHA was known to be important for infant development, alongside ARA, and both these fatty acids had been shown to be present in breast milk. The importance of DHA and ARA resulted in the joint FAO and WHO recommendation in 1994 that the fatty acid composition of infant formulas should correspond to the proportion of these fatty acids in breast milk, and as discussed below by 2000 DHA and ARA oils derived from microorganisms were being added to infant formula.

88. As early as the 1980s and 1990s the dietary supplements market was replete with fish oil products. Fish oil is produced as a byproduct of fish meal production. Fish meal, a major component of commercial animal and aquaculture feed is made from fish carcasses and offal after the water and oil is removed, and is a valuable source of protein, essential amino acids, vitamins, and minerals that was, and still is, used all around the world. However, the industrial production of fish meal involves process steps that can result in excessive oxidation of the fish oil and inclusion of oil-soluble contaminants, and attempts to utilise fish oils as an ingredient in food products were unsuccessful due to their strong fishy taste and odours. Furthermore, even once cleaned up and purified, a typical fish oil will only contain between 5-10% DHA and 25-30% EPA, with cold-water fish, such as tuna, salmon, mackerel, herring, and sardines, containing the highest amounts of DHA and EPA. Because of the cost of contaminant clean-up, the resulting low level of DHA, and sustainability issues, researchers began looking for alternative sources of triglyceride oils which contained higher levels of DHA, or for ways of artificially elevating the DHA content of an existing triglyceride oil.

89. It was known to be desirable to have EPA and DHA concentrations at levels higher than those naturally present in the fish oils, and there were a variety of techniques which were considered and/or had been used to increase the EPA and/or DHA concentration of a fish oil.

90. Urea fractionation and molecular distillation processes were the two well-known methods to concentrate omega-3/6 fatty acids that provided different concentrations of the fatty acids than were available naturally. Urea fractionation is a technique where saturated or monounsaturated fatty acids are trapped in crystals of urea at low temperatures, leaving behind a liquid that is highly enriched in PUFAs. Molecular distillation separates fatty acids according to their boiling points, which in turn is related to their chain length and number of double bonds, which allows fractions enriched in DHA or EPA to be obtained. Both processes work by preferentially removing undesirable fatty acids to concentrate the level of the desired fatty acid as a percentage of the total fatty acids, resulting in an enriched oil.

91. Desirable nutritional supplements in the form of structured lipids were also produced from fish oils. Structured lipids are lipids that have undergone synthetic molecular modification, either chemically or enzymatically, to alter their natural biosynthetic form, by enriching a desired fatty acid. The modifications can change the nutritional value or physiochemical properties of the starting oil, for example to increase the bioavailability of the fatty acids in the oils or enhance solubility, which are potentially desirable outcomes when manufacturing food, pharmaceutical and cosmetic formulations.

92. Although the enriched oils and structured lipid products produced from fish oils were used to manufacture more desirable oils, there were significant environmental and commercial drawbacks to producing enriched oils and structured lipids (e.g. the chemicals required and/or energy demands). These drawbacks meant there was a desire to find alternative sources of essential fatty acids that were more economical and environmentally friendly.

93. As noted above, the disadvantages of using fish oil as nutritional supplements were well understood. The key to finding an alternative source of PUFAs to fish oil came with the realisation in the early 1990s that the fish themselves do not naturally produce DHA and EPA (as they lack the key enzymes required) but instead obtain it from their diet of marine microbes, including marine algae. Marine microbes represent the primary food source for all sea life, including fish who ultimately derive most of their PUFAs from marine algae. Scientists therefore started investigating these marine algae as potential producers of PUFA rich oils.

94. Microorganisms are organisms that can only be seen through a microscope. Scientists would mainly use the scientific name of microorganisms to refer to different types of organisms. The scientific names of microorganisms are Latin based names that identify the organism based on their taxonomy. They encapsulate their genus and species. Whilst all organisms have a scientific name (e.g. humans are Homo sapiens), the scientific designation is particularly useful in microbiology as there are a large number of different microorganisms and they are often described by reference to their taxonomic ranking.

95. There are 8 levels in the taxonomic hierarchy, and below is the taxonomic hierarchy of a human for illustrative purposes:

Figure 7: Taxonomic rankings

96. Taxonomy is a specialist field, but the Skilled Person/Team would understand that microorganisms are classified by taxonomists (with input from geneticists) based on morphology and genetic similarity (in combination).

97. The overwhelming majority of microorganisms have the ability to produce a range of fatty acids, predominantly as phospholipids and/or TAGs. The production of fatty acids and their incorporation into phospholipids are physiologically necessary (e.g. for cell growth) and, therefore, are part of cellular primary metabolism. In contrast, the accumulation of TAG (storage lipid) is not a physiological necessity and is not a universal feature of all living cells. Storage lipid accumulation is an example of secondary metabolism (see paragraphs 73 to 78). This means not all microorganisms accumulate significant quantities of TAG. Species which do not accumulate storage lipid are designated non-oleaginous microorganisms and contain less than 25% (dry weight) as lipid - the majority of which is phospholipid in the membranes of the cell. In contrast, oleaginous microorganisms may contain greater than 25% (dry weight) cell lipid under suitable conditions, the majority being in the form of storage TAG.

98. There had been many unsuccessful attempts to produce commercially viable microbial oils from oleaginous microorganisms dating back to the Second World War, although the possibility of microbial oils had been known since the 1890s. The key reason for the historic failure of microbial oils was the lack of large-scale fermentation technology that rendered their production too costly and difficult.

99. Heterotrophic microbial oils (i.e. those produced by fermentation, which does not require light) needed a large amount of nitrogen and carbon in order for the microorganisms to grow. For every 1000kg of oil to be produced, >10,000 litres of culture had to be grown and 5,000kg of sugar metabolised. This meant microbial oils were unable to compete with the cost and efficiency of producing oils from traditional animal and plant sources using mature methods of production and processing. Attempts to utilise autotrophic microorganisms (usually types of photosynthetic microalgae) to decrease the cost of microbial oils were actually more difficult, and have never been successfully deployed at a commercial scale. The major challenge had been that the large and open ponds necessary to expose the culture to sunlight created difficult to control environmental conditions, which can easily result in contamination. They also result in very low cell densities (<5 g/l) and high harvesting costs that make them ultimately more expensive than heterotrophic fermentation and therefore less commercially attractive.

100. The first commercially viable microbial oil was the γ-linolenic acid (18:3n-6, GLA) identified by Professor Colin Ratledge. GLA is the active ingredient in evening primrose oil, which had been historically used as a folk remedy for a range of conditions. Despite initial success when launched in 1985, the production of this microbial oil was halted after around six years when a plant alternative was identified in the form of borage oil.

101. There remained a continued interest in microbial oils, both academically and industrially. Specific microorganisms and microbial oil products are discussed below, but in summary by 2002 it was understood that:

i) The number of oleaginous microorganisms was relatively small in comparison with the total number of species.

ii) The oleaginous microorganisms were mainly species of yeast and fungi (including moulds); few bacteria produced much extractable edible oil.

iii) The oils produced by these microorganisms were similar to plant oils, mainly composed of triglycerides comprising fatty acids similar to vegetable oil, although often in different distributions relative to those found in plant oils.

iv) Some algae produced fairly high amounts of lipid that tended to be more complex in their fatty acid profile compared to those from the yeasts and fungi. However, they also contained the same fatty acids that occurred in plant oils and some PUFAs were observed to be like those found in fish oils.

v) Oil accumulation in the highest producing microorganisms could be increased by starving the cells of a supply of nitrogen (or a nutrient other than carbon). The cells generally responded to the deprivation of that key nutrient by no longer dividing and entering a lipid storage phase in which the excess carbon, still present in the growth medium, was converted into storage lipid in the form of triglyceride. If the cells were subsequently returned to a situation where nitrogen was available, the oil reserves would be quickly mobilised and rechannelled, and the cells would start growing and dividing again. Lipid accumulation was discovered to be a stress-induced response with the triglyceride oil being an intracellular energy storage material.

102. A typical profile for the accumulation of lipid in an oil-producing microorganism is shown below in Figure 8 which is taken from Chapter 1 of Single Cell Oils (first edition, 2005).

Figure 8: An idealised representation of the process of lipid accumulation in an oleaginous microorganism

103. This meant oleaginous microorganisms that produced high levels of a fatty acid of interest could be used to manufacture oils.

104. Oils produced directly from microorganisms were termed “microbial oils” or “Single Cell Oils” (“SCOs”). The annotated table from a review article dated 2002 (Ratledge and Wynn (2002) “The Biochemistry and Molecular Biology of Lipid Accumulation in Oleaginous Microorganisms” Advances in Applied Microbiology, Volume 51) shows the simple and rich fatty acid profiles of some oleaginous heterotrophic microorganisms that would have been known by that time to be in use, or considered to be used, as SCOs. The table shows the wt% of total fatty acids in the cells, alongside the wt% of individual fatty acids as a percentage of total fatty acids:

105. Yeasts are unicellular fungi and there were a number of oleaginous yeasts that were considered for use as sources of SCOs, in particular yeast oils were considered interesting as a potential source of a cocoa butter equivalent. It was considered a desirable SCO target, as it is a high value product used to make chocolate, and at the time of this product development cocoa butter prices were at a record high.

106. Moulds are fungi which grow as multicellular filaments to form a colony, and some of the most interesting moulds at the EP 155 Priority Date in May 2002 were organisms of the Mortierella genus, as species within this genus had been shown to produce substantial amounts of arachidonic acid. By 2002 an ARA oil produced from Mortierella alpina, often referred to as ARASCO, had been approved by the US regulatory body for inclusion in infant formula, together with DHA from the microorganism Crypthecodinium cohnii (discussed below). The high prices commanded in the infant formula market rendered it commercially viable to produce these essential fatty acids from a microbial source for this use.

107. There are three species of microorganisms (Crypthecodinium cohnii, Schizochytrium limacinum and Thraustochytrium aureum) identified in Table 1 at paragraph 104 above, which are grouped together as “algae”. This term was often used to describe microorganisms that were photosynthetic (or were considered to have once been photosynthetic and had lost their ability to photosynthesise at some point during their evolution). The term was used to describe oil produced from these organisms in marketing and sales literature.

108. Crypthecodinium cohnii is a marine dinoflagellate. The majority of dinoflagellates are photosynthetic. However, Crypthecodinium cohnii was identified by Martek in the late 1980s and is heterotrophic (it grows on glucose in the dark), does not contain chloroplasts, and produces no PUFA in its cell lipid in any appreciable amount other than DHA. This DHA rich oil is also accumulated primarily as triglyceride which, as noted above, is the preferred form of lipid for food use.

109. The commercialised SCO produced from C.cohnii by Martek was referred to as DHA Algal Oil or “DHASCO”. Regulatory approval for DHASCO (together with ARASCO) to be used in infant formula was granted in 2001. DHASCO was also available as an over-the-counter nutritional supplement for adults.

110. For the purposes of illustration, an electron micrograph image of Crypthecodinium cohnii cells is shown below. This shows the cells towards the end of the growth phase (when the nitrogen supply has been limited but carbon continues to be supplied). The image shows the cells packed with lipid bodies (sometimes called “fat globules” or “oil bodies”) which constitute over half the dry cell weight.

Figure 9 - C.cohnii cells with lipid bodies visible

111. Schizochytrium limacinum and Thraustochytrium aureum are closely related species of the taxonomic order Thraustochytrid. In 2002 “Thraustochytrium” and “Schizochytrium” belonged to the Thraustochytrid order.

112. Thraustochytrids were also known to produce DHA (as shown in Table 1 above), but unlike C.cohnii where the only long-chain PUFA produced was DHA, Thraustochytrids were also known to produce docosapentaenoic acid (“DPA”) (22:5 n-6). By 2002, DHA from Thraustochytrids had not been approved for use in infant formula, but the oil was sold as a nutraceutical supplement under the commercial name SeaGold (later DHAGold and subsequently S-type DHA / DHASCO-S). The biomass of the Schizochytrium produced by the company OmegaTech had been used as a supplement for aquaculture feed, poultry feed to produce eggs rich in DHA, and to produce DHA-enriched milk from dairy cows.

113. The American Type Culture Collection (referred to as “ATCC”) is a nonprofit organisation based in Virginia, USA which collects, stores, and distributes standard reference microorganisms, cell lines and other materials for research and development, including those deposited in association with filing patent applications based on those materials. The Skilled Person/Team could have obtained microbial strains which had been deposited and maintained at the ATCC (or other similar well-known culture collections). The Skilled Person/Team could also have collected and isolated their own microbial strains from nature.

114. Below is a summary of how a microbial oil was made, mainly by reference to Martek’s DHASCO oil (DHA from Crypthecodinium cohnii), using annotated figures from the Single Cell Oils book:

Figure 10: Overview of DHASCO microbial oil production (to drying step)

115. Steps A, B and C which have been marked on Figure 10 involve:

i) Initial inoculation - The cell line (often stored in vials at -80°C until needed) is used to inoculate small volume shake flasks containing starter media (containing nutrients for growth, and optimised in terms of salinity, pH etc.), and a series of shake flasks of increasing volume are used as the cells multiply (often referred to as the biomass increasing).

ii) Seed train - As the cells multiply, and the biomass increases further, the composition is transferred to a moderately sized seed fermenter, generally made from stainless steel, and media to encourage growth continues to be supplied. Again, usually a series of seed fermenters of increasing volume would be used. The fermentation growth media contains a low-cost carbon substrate (typically glucose) as well as a nitrogen source (typically ammonia, ammonium sulphate, yeast extract or yeast peptone) and other micronutrients and essential vitamins.

iii) Production - The growing biomass is then transferred to a larger production fermenter (e.g. 100m3, and about 10 times the size of the final seed train fermenter), again usually made from stainless steel. The fermentation tank which is used to grow the microbes is sparged with air, which provides the necessary oxygen to drive the cellular aerobic metabolism and flushes away any carbon dioxide in the exhaust. The contents of the tanks are typically mixed during fermentation to break up the sparging air bubbles, thereby improving the oxygen transfer to the cells and maximizing growth. This also helps avoid the cells aggregating (clumping together). However, these processes of sparging and mixing can in turn lead to foaming, which if left unchecked could even cause the fermenter to overflow. Consequently, an antifoaming agent is always added to the fermenter. Surfactants were (and still are) commonly used as antifoaming agents, as they decrease the surface tension thus reducing the formation of bubbles and therefore foam.

116. Under ideal growth conditions, the culture will grow exponentially and in this phase the cells are not producing significant levels of triglyceride lipids. Once the biomass has increased to target volume, the conditions are altered to encourage the accumulation of lipids (instead of the cells continuing to multiply). In particular, it was well known that limiting available nitrogen will slow down growth and, when provided at the same time with excess energy (e.g. glucose), oil producing organisms will typically switch their metabolism from growth to accumulation of oil as an energy store.

117. Next, at step D above, the biomass (microbial cells) can be heat-treated to pasteurise the cells to stabilise them, by inactivating the cell’s natural metabolic processes that may damage or consume the intracellular lipid. The biomass is then concentrated and separated from the growth media (called ‘harvesting’ the cells).

Figure 11: Examples of different types of centrifuge

118. In the production of DHASCO, this harvesting was through centrifugation. In general (i.e. not limited to the production of DHASCO), centrifugation involves spinning a solution at high speed in order to separate components of different densities through the use of centrifugal force. A simple bench-top centrifuge involves spinning test-tube like vials, leaving the lighter, less dense phase at the top of the vial and the heavier, denser phase at the bottom of the vial. On a small or laboratory scale, centrifugation was typically performed using a swinging bucket or fixed-angle centrifuge, where discrete volumes of the sample are spun simultaneously, and the supernatants and pellets are pooled after centrifugation. In large-scale operations, continuous flow centrifuges (e.g., bowl centrifuges, disc-stack centrifuges, or decanting centrifuges) were extensively used for liquid/liquid separations. In a disc-stack centrifuge, centrifugal force separates the heavier aqueous layer from the lighter oil layer in a horizontal mode, with the heavier water layer discharging farthest from the centrifuge’s central axis of rotation and the lighter lipid layer discharging closest to the central axis. Adjustable dams allow fine-tuning of the separation point between the two phases. The main advantage of continuous flow centrifugation is its efficiency; the centrifuge does not need to be shut down during harvesting. Instead of gravity, centrifugal force - ranging from 4,000 to 14,000 times gravitational force in disc-stack centrifuges - drives the separation.

119. During the centrifugation of cells carried out for the production of DHASCO most, but far from all, of the liquid media in the fermentation broth is separated off. The resulting biomass is dried as shown in step E, and spray drying was a common technique. The goal was to obtain a powder of mostly intact dried cells, as if the lipid remains within the cells it is more (although not totally) protected from the effects of oxidation. This enables the biomass to be stored for a period of time if necessary.

120. The production of sunflower oil, vegetable oil, rape seed oil, etc. was many decades old by 2002, and there was a lot of knowledge on techniques for extracting those oils, which had been proven to work on industrial scale. The process of growing microorganisms in a broth of liquid media is inevitably very different to growing plants, but the industry leveraged the very well-established oil extraction techniques from plant / seed oil production. Therefore, one aim of the drying process in step E was to obtain a solid product which could then be treated in a similar way to plant matter or seeds.

121. The first extraction techniques used for microbial oils were adapted from this decades old hexane extraction technology used in the vegetable / seed oil industries. However, hexane extraction still had certain drawbacks, as it is a hazardous substance in the factory due to its volatility and flammability. The downsides of hexane extraction were well known in 2002, but microbial oil production on a commercial scale was still relatively new at that date.

122. The next diagram from the Single Cell Oils book shows how the dried cells are treated, and the oil extracted, to produce crude DHASCO oil:

Figure 12: Overview of microbial oil production (to produce crude DHASCO oil)

123. As shown in step F, the next step in the production of DHASCO is to re-constitute the dried cells in a solvent (usually hexane) to make a slurry, and then use a ‘cell disrupter’ to lyse the cells (i.e. disrupting the cell walls to release the intracellular components).

124. A simple and effective means of disrupting cells is by the use of mechanical techniques. The two major mechanical techniques used to manufacture SCOs at the EP 155 Priority Date in May 2002 were:

i) High pressure homogenisation: This type of homogenisation involves subjecting the cells to very high pressure, and forcing the hexane-cell slurry through a narrow gap into a lower pressure environment, thereby creating shear forces which burst the cells open. The stream of cells could also be directed at a blade or plate where the high-speed collision aids in cell lysis. This was the method used in the process to manufacture DHASCO by Martek.

ii) Bead milling: (a.k.a. bead beating) This involves adding the hexane-cell slurry to a chamber containing beads (generally made of glass, ceramic or steel) and subjecting them to high-speed agitation, such as vortexing. The cells are physically ground against the beads, causing the cell walls to be disrupted and the intracellular components to be released. This technique is generally effective in lysing even very tough cells (and was commonly used to grind seeds to make seed oils), however it is harsher than other methods. This was the method used in the process to manufacture S-type DHA by OmegaTech.

125. Other lysis techniques at the EP 155 Priority Date in May 2002 were also known, but were not used in the commercial production of SCOs. Which techniques were or were not known is the subject of dispute, which I resolve later.

126. As mentioned above, as part of the extraction process for DHASCO the dry cells were first mixed into a slurry with an organic solvent prior to lysis. Lipids are insoluble in water, but soluble in suitable organic solvents. This means that lipid in the cells dissolves into the solvent, extracting the lipid from the dried biomass and leaving behind the other components, allowing separation. Hexane was the preferred and most commonly used solvent in industrial extraction processes in 2002. Hexane is a non-polar organic solvent well suited to dissolving non-polar lipids such as TAGs, which are released when the cells are disrupted. Again, this built upon the established practice of using hexane to extract oil from plant matter / seeds. The hexane-oil mixture, called the ‘miscella’, was then separated from the oil-depleted biomass, as shown in step G, using a centrifuge or decanter.

127. Finally, as shown in step H, the miscella (i.e. oil/hexane mixture) was passed on to an evaporator to remove the hexane (which is recovered and reused), leaving the crude oil as shown at I.

128. The FRIOLEX process was first developed in 1998, in the plant / seed oil context, as an alternative to traditional hexane-based downstream oil extraction. The FRIOLEX process starts with wet biomass following which the microbial cells are lysed in order to release the oil. The resulting water / lipid mixture (which takes the form of an emulsion) is treated with isopropanol (or a similar polar solvent) in water, agitated and then centrifuged. The water-miscible isopropanol makes the aqueous phase even more polar, and so less favoured by the non-polar lipids (such as TAGs). The small droplets of non-polar lipid therefore coalesce into larger lipid droplets, and the composition separates into a light oil phase and a heavy water/solvent phase, which can be separated using centrifugation. It was also known that salt could be added to increase the density of the heavy water/solvent phase and encourage better separation. The FRIOLEX process therefore offered a clear advantage, as hexane could be avoided. However, one disadvantage was that extractions tended to be less selective as compared to hexane. Moreover, the solvent needed to be recovered from the aqueous phase, which was challenging, as part of the point of the process was that the solvents were selected to be water-miscible.

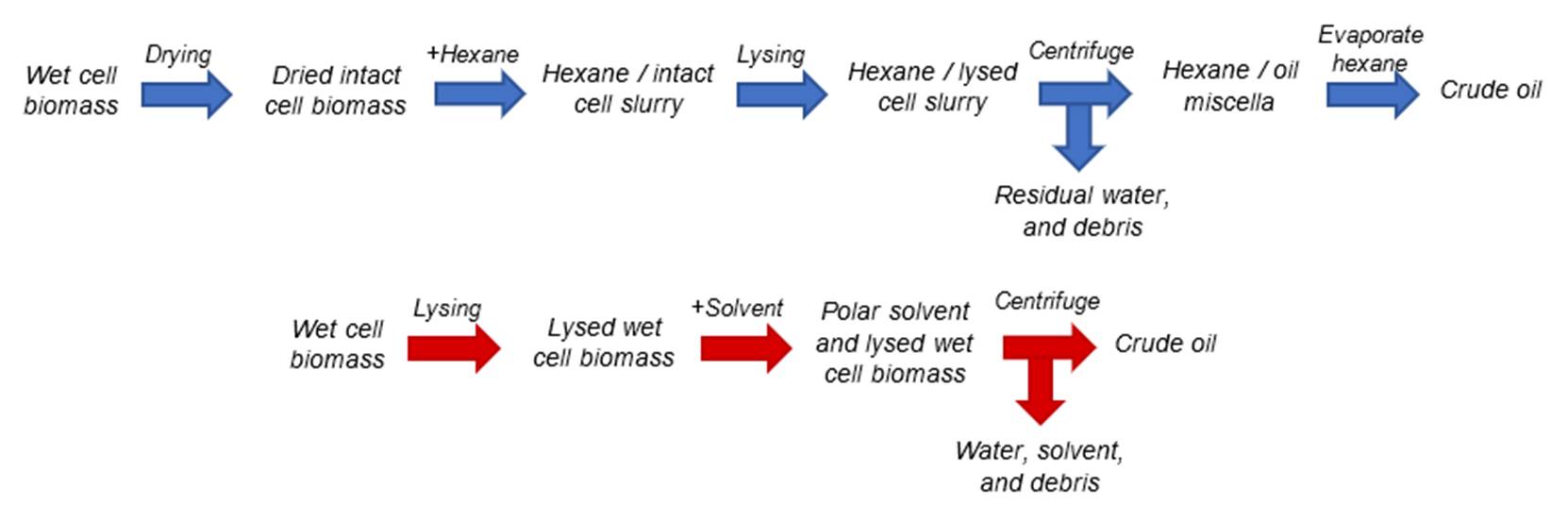

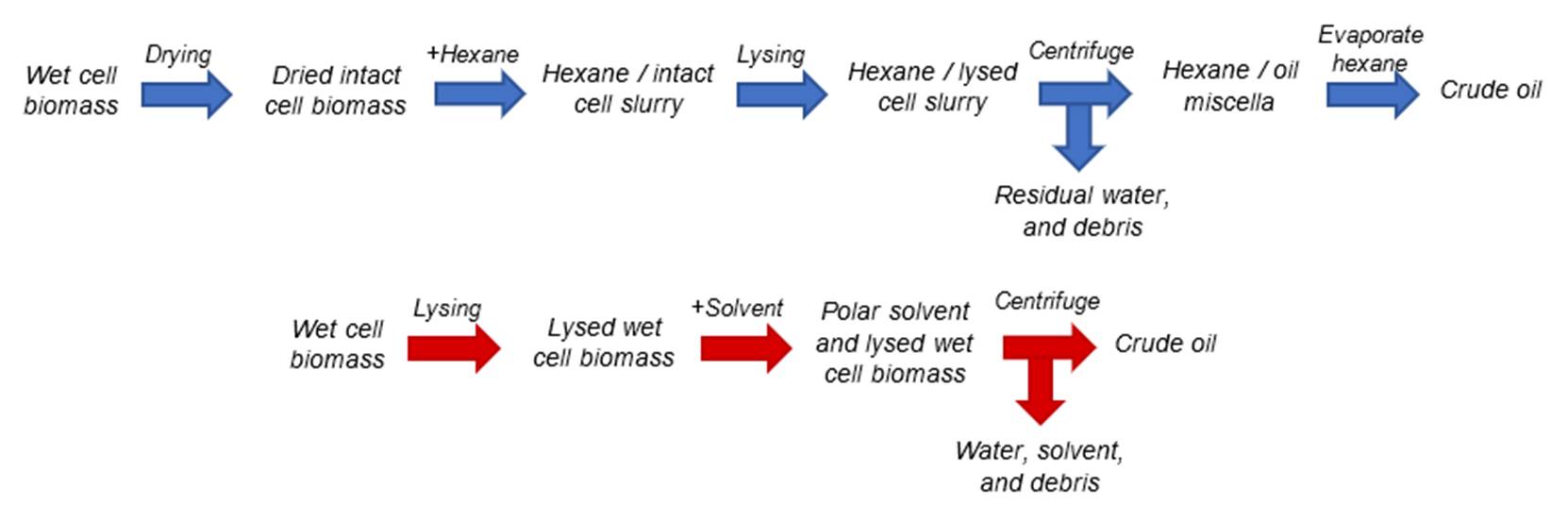

129. The differences between traditional hexane extraction and the FRIOLEX process can be summarised as below:

Figure 13: Outline comparison of hexane (top, blue) and FRIOLEX (bottom, red) methods

130. Although the Skilled Person/Team would have been aware of the FRIOLEX process in 2002, it had not at that point been implemented in a commercial scale microbial oil production process. Nevertheless there was increasing interest in the FRIOLEX process.

131. It had also long been appreciated that, in an ideal situation, the extraction process would be entirely aqueous. However, inherent in this was the likelihood that an emulsion forms between the lipid and water/other aqueous components. An emulsion is a mixture of two (or more) liquids that are normally immiscible, but where one liquid is present as microscopic droplets distributed throughout the other liquid(s). The more energetically stable the emulsion, the more difficult it will be to ‘break’ and separate the liquids. In standard solvent extraction, one reason that the biomass had to be dried (typically one of the more expensive steps in the production process) was that hexane and wet cells form an extremely stable emulsion under certain conditions that is very challenging to break.

132. Once oil had been extracted and processed, any organic solvent used in the extraction process needed to be removed. Thus:

i) Hexane was evaporated off (Dueppen XX [T2/104/4-12]).

ii) Any solvent used had to be removed so that it was only there in very small quantities, particularly if the lipid was to be used in a foodstuff (Dueppen XX [T2/166/21 - 167/4, 271/16 - 272/4]).

iii) This applied equally to a polar organic solvent in the FRIOLEX process - the oil at the end of the process would be understood to be substantially free of both water and organic solvent (Dueppen XX [T2/267/13-19]).

133. The result of the process described above is a crude oil, which may still contain some impurities. PUFA oils are very sensitive to degradation, and even relatively small amounts of certain impurities can lead to oxidation, discoloration, an unpleasant odour, or cloudiness at low temperatures.

134. The processing of microbial crude oils has followed the processes and principles applied to the refining of vegetable oils over the past 100 years. Crude microbial oils, like crude vegetable oils, are typically unfit for human consumption as they contain numerous impurities and often have an odour and unacceptable taste. Impurities which are removed include water, free fatty acids, phospholipids, minerals, carotenoids, sterols, antioxidants, waxes and residual cell debris. Since microbial oils are sensitive to oxidation, care needs to be taken over these techniques. In contrast to crude oils produced from fish, crude microbial oils are free from pesticides, insecticides, heavy metals and other pollutants often found in fish oils. Nevertheless, downstream processing would have been undertaken as a matter of course for oils which were to be incorporated into food products or any other products for human consumption.

135. A trio of steps called refining, bleaching and deodorisation form the standard process, which is commonly abbreviated to RBD. These techniques are essentially identical to those used for many decades in the plant / seed oil industry, which had been developed, automated, and made into a continuous process by the 1950s.

136. Refining involves both degumming (a water washing process which removes phospholipids by hydrating them to form a sludge / gum) and neutralisation (fatty acids are neutralised by the addition of sodium hydroxide making them more soluble in water, so again can be separated from the oil with a water wash). The purpose of bleaching is to improve the colour of the oil by removing the remaining impurities including pigments, trace metals, and oxidation products. Deodorisation, the last step in the overall refining process, aims to remove odiferous small molecules.

137. The oil may also undergo winterisation, which is sometimes considered a separate precursor to RBD, but sometimes considered a refinement step itself (and the acronym RBWD is sometimes used). Winterisation is a type of fractional crystallisation involving cooling the oil, so that the components with higher melting points (e.g. saturated fatty acids) solidify (crystallise). The precipitated components can then be separated from the liquid (e.g. via filtration). The aim is to achieve an oil which remains clear and does not turn cloudy at low temperatures.

138. The result of these steps is a refined oil, which can be incorporated into various products.

139. As the process to make a microbial oil is a biological one, the percentage of the relevant fatty acid obtained (e.g. DHA) would vary in each production run by a few percent. Therefore, it was also common to blend different batches of a refined oil together, and also to dilute refined oil with a small amount of another oil (e.g. sunflower oil), to make a standardised product. For example, in the case of DHASCO, after refining, bleaching, winterisation and deodorising, tocopherols and antioxidants were added to the oil to prevent any further oxidation, following which it was blended with high-oleic sunflower oil to a standardised 40% DHA for commercial sale.

140. PUFAs are generally highly susceptible to oxidation. Oxidation causes the lipids to change in flavour, odour and also colour, in turn causing the oil to become rancid, limiting its shelf-life, and causing a ‘fishy’ smell and taste. Oxidation is a risk throughout the production process and during storage - it can be caused, or accelerated, by exposure of the PUFAs to oxygen, heat, light, oxidative enzymes, certain metals etc. As such, processes were designed to minimise the extent of oxidation. Common steps taken included de-oxygenating using inert gases such as nitrogen, pasteurising to deactivate endogenous enzymes, and adding chemical antioxidants to the oil when storing.

141. There are two very common analytical measures of PUFA oxidation which each provide a simple numerical value, in both cases a lower value indicating less oxidation:

i) Peroxide value (PV) is a measure of the amount of peroxide present in a lipid sample. The primary oxidation of lipids predominantly causes the formation of hydroperoxides, which are captured in the PV, and so PV is a measure of the components produced in the early stages of oxidation. As such it provides a ‘snap shot’ of the oxidation status of a sample at a single point in time.

ii) Anisidine value (AV) (also referred to ρ-AV or AnV) is a measure of secondary oxidation of a lipid sample. As it can capture the products of oxidation occurring over a period of time, AV is considered to be a useful measure of the ‘oxidative history’ of a sample.

142. Bill Barclay was a prominent figure in the field of microbial oils, and both Dr Wynn and Mr Dueppen were previously aware of the work reported in the Barclay prior art (Wynn 1 ¶111; Dueppen 1 ¶79). Dr Barclay’s company was OmegaTech, and OmegaTech patents were a source of information about thraustochytrids including Schizochytrium (Wynn 2 ¶16).

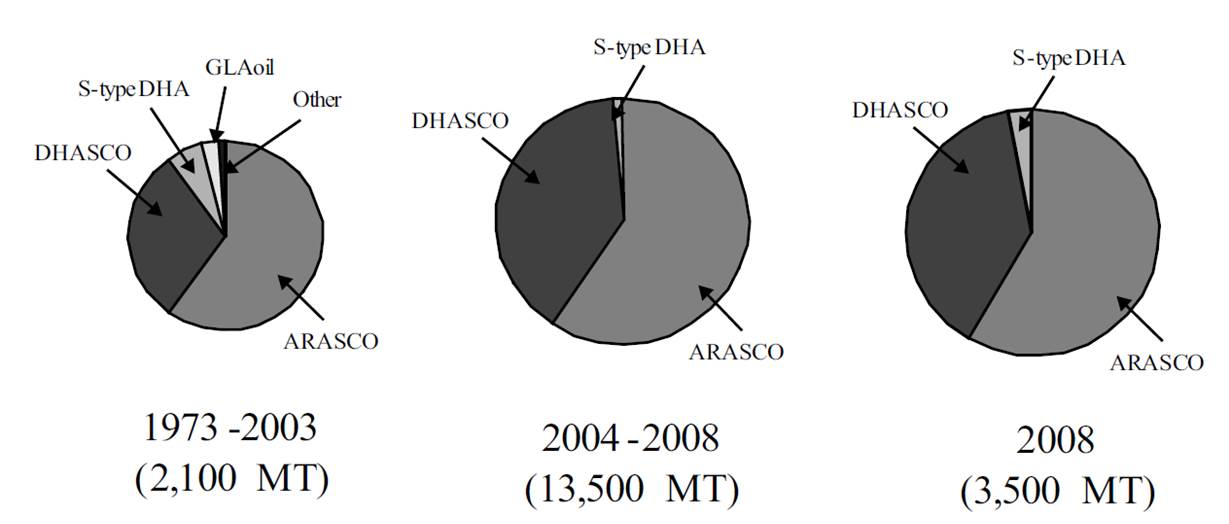

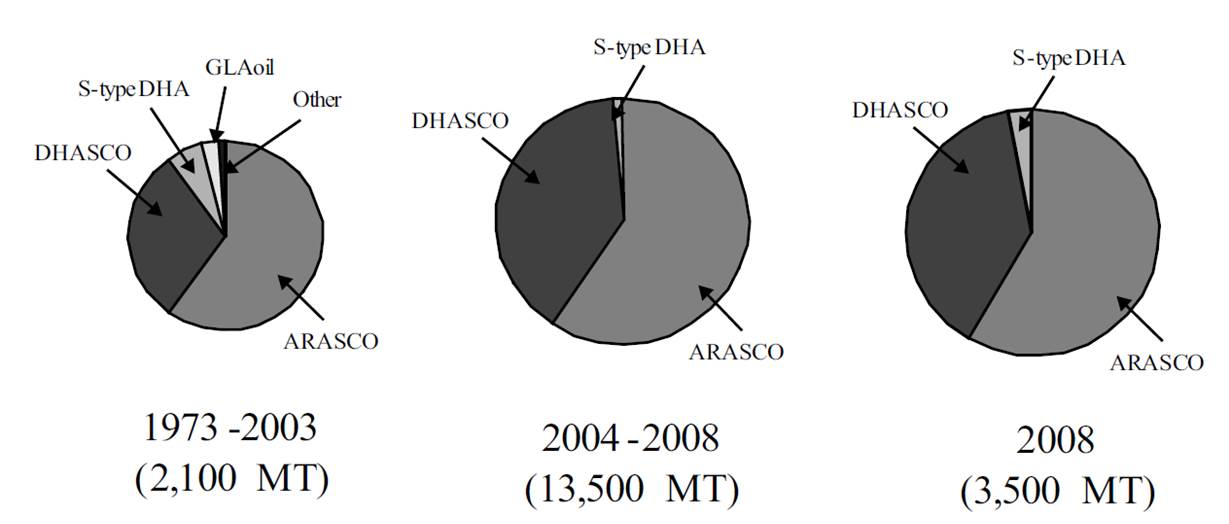

143. Barclay had identified a Schizochytrium strain that was deposited as ATCC 20888. It was CGK in 2002 that this was the source of OmegaTech’s commercial DHA oil, known inter alia as S-type DHA (Wynn 1 ¶¶102-103, 276; Agreed CGK - see above). While Martek’s DHASCO and ARASCO dominated the market, S-type DHA had a notable part of the total sales of microbial oils in the period up to 2003 (Figure 10 at Wynn 1 ¶101).

144. Both Dr Wynn and Mr Dueppen agreed that Schizochytrium strain ATCC 20888 was well known in 2002 as a good source of DHA (Dueppen XX [T2/100/3 - 101/9, 148/16-19]; Wynn XX [T4/447/25 - 449/4]).

145. Mr Dueppen exhibited Chapter 3 of the first edition of Single Cell Oils as describing OmegaTech’s CGK process in 2002 for producing S-type DHA from this strain (Dueppen 1 ¶58; [C4/3]). Chapter 13 of the first edition of Single Cell Oils also refers to this use of Schizochytrium ([D2/4/56]; Dueppen XX [T2/122/4 - 123/24]).

146. Going into the trial, DSM maintained that certain advantages associated with Barclay’s Schizochytrium strain (as set out at paragraph 88 of the Statement of Agreed CGK [B1/35/305]) were not CGK in 2002, but had become so by 2009 - this was point 5 in the List of Disputed Issues. Mara’s position was that this information was already CGK in 2002, and this was confirmed by Dr Wynn [T4/450/12 - 452/16].

147. These advantages, as compared to the production of DHASCO from C.cohnii, were:

i) The Schizochytrium strain grew at low salinity - an advantage for growth in standard stainless steel tanks. See Wynn XX [T4/451/23 - 452/3].

ii) Low dissolved oxygen levels had been shown to induce thraustochytrid DHA production. This meant that the Schizochytrium strain used to produce S-type DHA could be grown in larger culture vessels without a concern for depletion of oxygen in different parts of the tank. This was in contrast to C.cohnii, which required oxygen to produce DHA. See Wynn XX [T4/452/8-12].

iii) The Schizochytrium strain grew to higher cell densities at a faster rate than C.cohnii. See Wynn XX [T4/450/21 - 451/22].

CGK Disputes regarding 3 May 2002

148. Here I set out and decide the remaining points in dispute on the CGK.